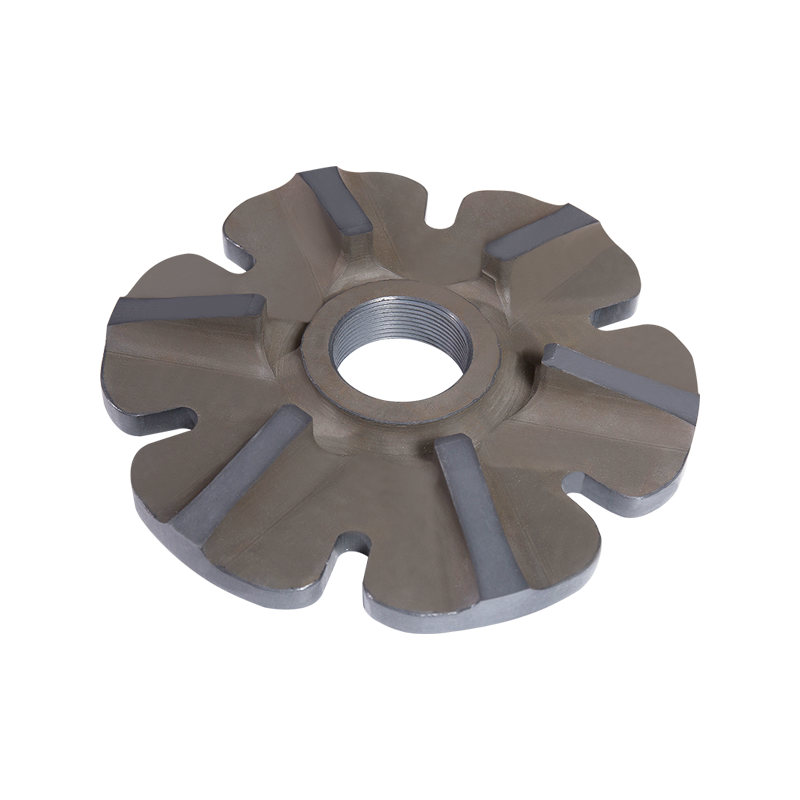

Application and advantages of silicon nitride degassing rotor in the casting industry

Material advantages of silicon nitride

Silicon nitride is a high-performance ceramic material with excellent high temperature resistance and wear resistance. Its melting point is as high as 1700°C, which enables it to maintain stable physical properties in high-temperature casting environments. At the same time, the low thermal expansion coefficient of silicon nitride enables it to show excellent dimensional stability when the temperature changes, making it suitable for high-demand casting processes.

In addition, the corrosion resistance of silicon nitride enables it to be used for a long time in the environment of various metal liquids, reducing the frequency of equipment replacement due to material loss, thereby reducing production costs.

Importance of the degassing process

During the casting process, the gas in the molten metal affects the quality of the casting, forming bubbles and defects. The silicon nitride degassing rotor uses the centrifugal force generated by high-speed rotation to quickly bring the bubbles in the melt to the surface, thereby achieving effective degassing. This process not only increases the density of the casting, but also enhances its mechanical properties.

In addition, the thermal conductivity of the silicon nitride degassing rotor enables it to quickly and evenly dissipate heat during the degassing process, avoiding deformation of the casting due to uneven temperature. This is especially important when manufacturing castings with complex shapes, ensuring product accuracy and consistency.

Application Cases

Silicon nitride degassing rotors perform well in applications with a variety of casting materials. For example, in aluminum casting, the degassing rotor effectively removes hydrogen from the melt and prevents porosity defects in the casting. In magnesium alloy casting, the corrosion resistance of the rotor protects the equipment and ensures the continuity and stability of production.

Not only that, silicon nitride degassing rotors are also widely used in the casting of high-end aerospace and automotive parts. As these industries continue to increase their requirements for casting performance, the market demand for silicon nitride degassing rotors will continue to grow.

Contact Us for Quotes and Prices!

Just let us know what you want, and we will get in touch with you as soon as possible!

English

English 简体中文

简体中文