How does aluminum titanate help improve the efficiency of the aluminum casting process

Aluminum titanate mainly achieves this through its unique physical and chemical properties in improving the efficiency of the aluminum casting process. The following is a detailed analysis and summary:

Low thermal expansion coefficient and high temperature stability: Aluminum titanate has a low average thermal expansion coefficient (9.5E-6/℃) and is one of the famous low thermal expansion materials.

It can be used at higher temperatures (1460℃) and can adapt well to oxidation problems at high temperatures.

These characteristics make aluminum titanate a stable mold or riser material in the aluminum casting process, reducing dimensional changes and thermal stress caused by temperature changes, thereby improving casting accuracy and efficiency.

Thermal shock resistance: Aluminum titanate has excellent thermal shock resistance and can maintain structural stability under rapid temperature changes.

This is especially important for the rapid cooling and heating process in the aluminum casting process, which can reduce the damage and replacement frequency of the mold or riser, improve production efficiency and reduce costs.

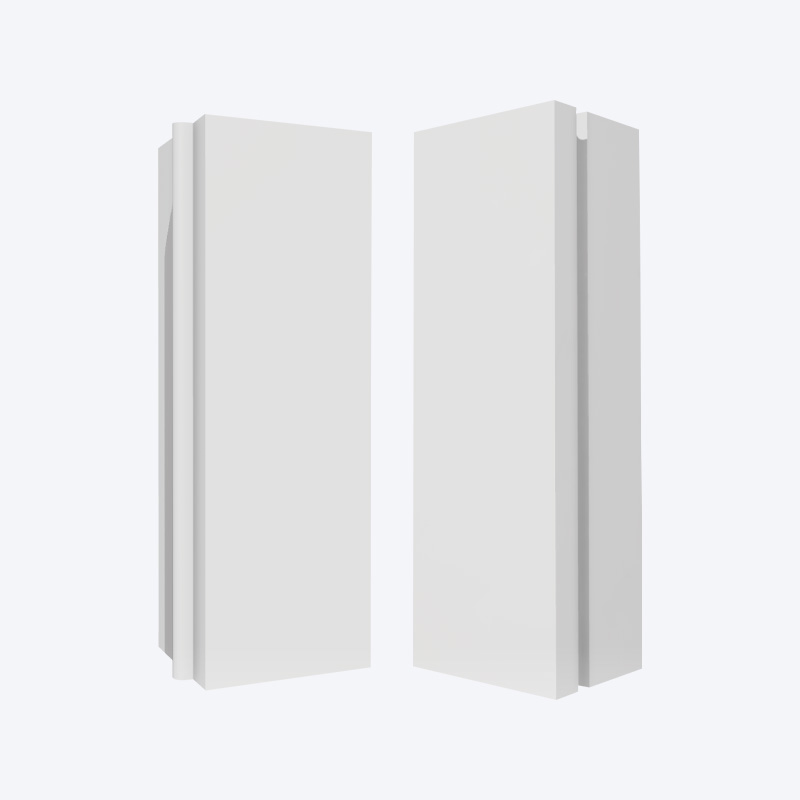

Non-wetting: Aluminum titanate is non-wetting to molten aluminum, which means that molten aluminum is not easy to adhere to the surface of aluminum titanate.

This feature can reduce the residual aluminum liquid in the mold or riser, reduce the frequency of cleaning and maintenance, and improve production efficiency.

Wear and corrosion resistance: Aluminum titanate has the characteristics of slag resistance, alkali resistance, corrosion resistance, etc., and can maintain a long service life in harsh working environments.

This is especially important for molds and risers that need to be used frequently in the aluminum casting process, which can reduce the replacement frequency and maintenance costs and improve production efficiency.

Synthesis method and modification: There are various synthesis methods for aluminum titanate, including solid phase method, liquid phase method and gas phase method, and the appropriate synthesis method can be selected according to different application requirements.

Modification by adding stabilizers (such as magnesium oxide, iron oxide, etc.) can further improve the performance of aluminum titanate, such as reducing the thermal decomposition temperature and improving the mechanical strength, thereby further improving its use efficiency in the aluminum casting process.

Aluminum titanate can play an important role in the aluminum casting process through its low thermal expansion coefficient, high temperature stability, thermal shock resistance, non-wetting, wear resistance and corrosion resistance, as well as a variety of synthesis methods and modification methods, improving production efficiency, reducing production costs and improving product quality.

Contact Us for Quotes and Prices!

Just let us know what you want, and we will get in touch with you as soon as possible!

English

English 简体中文

简体中文