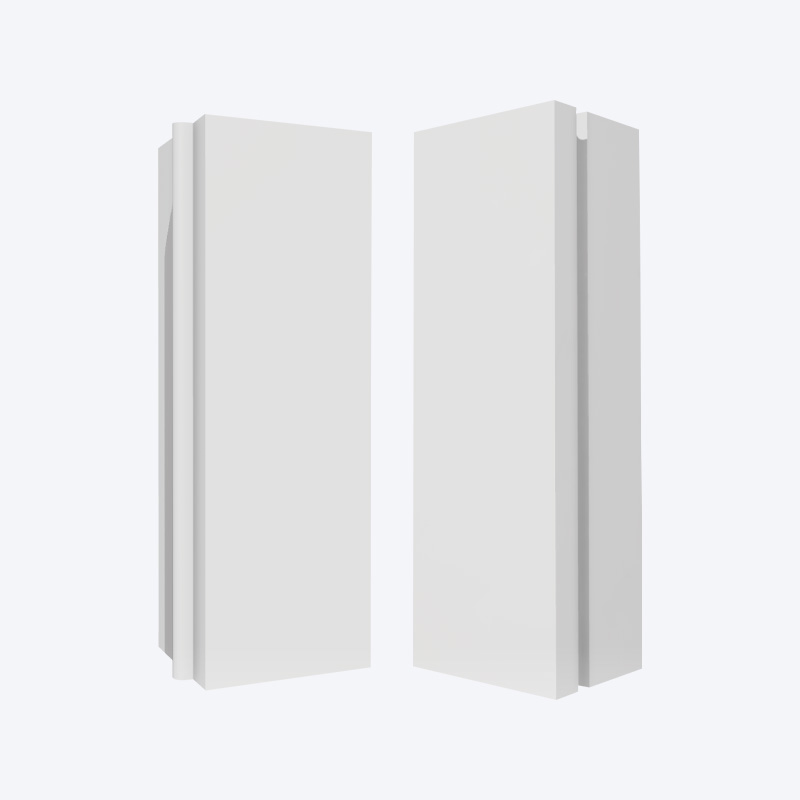

Heater Protection Tube: Technical Details

In various industrial and experimental applications, heating elements are often used to provide the required heat. However, in order to ensure the efficiency and safety of the heating system, these heating elements must be properly protected. This is where the Heater Protection Tube comes into play.

1. Material Selection

The main function of the Heater Protection Tube is to protect the heating element from the external environment and prevent it from direct contact with possible corrosive gases or liquids. To this end, it is crucial to select the appropriate material. Commonly used protection tube materials include:

Stainless steel: Stainless steel is the most commonly used material for Heater Protection Tubes due to its excellent corrosion resistance and high temperature performance. 304 and 316 stainless steels are often used for general heating applications, while higher grade materials such as Inconel are used in more demanding environments.

Ceramic: Ceramic protection tubes have excellent high temperature resistance and electrical insulation properties, making them ideal for high temperature heating applications. They can remain stable at extreme temperatures, but are relatively fragile and prone to breakage.

Quartz: Quartz protection tubes are known for their excellent transparency and good thermal stability. They are often used in applications that require visual monitoring of the heating process, such as smelting and heat treatment.

2. Design points

When designing a heating protection tube, several factors need to be considered to ensure its effectiveness in practical applications:

Size and shape: The size of the protection tube must match the size of the heating element. An oversized protection tube will result in reduced heat transfer efficiency, while an undersized protection tube may not provide adequate protection. Common shapes include cylindrical and tubular, which need to be selected according to the specific installation space and usage conditions.

Thermal conductivity: The material of the protection tube should have good thermal conductivity to ensure that the heating element can effectively transfer heat to the target area. At the same time, the thermal conductivity of the protection tube should be as low as possible to reduce heat loss and maintain a stable heating effect.

Corrosion resistance: In some chemical or corrosive gas environments, the protection tube must have a high degree of corrosion resistance. This usually requires the selection of specially designed materials and coatings to prevent the protection tube from being corroded or degraded during use.

Mechanical strength: The protection tube must have sufficient mechanical strength to withstand physical shock and pressure during operation. Especially in high temperature and high pressure environments, the strength of the protection tube is an important factor in ensuring the safety of the heating system.

3. Application fields

Heating protection tubes are widely used in many fields, including:

Industrial manufacturing: In industrial processes such as metallurgy, chemical industry and food processing, heating protection tubes are used to protect heating elements and ensure the stable operation of the heating system.

Laboratory equipment: In scientific research and laboratory equipment, protection tubes are used to ensure that heating elements are not affected by the external environment during high-temperature experiments.

Household appliances: In household appliances such as electric kettles and electric ovens, protection tubes help improve the safety and durability of the equipment.

Contact Us for Quotes and Prices!

Just let us know what you want, and we will get in touch with you as soon as possible!

English

English 简体中文

简体中文